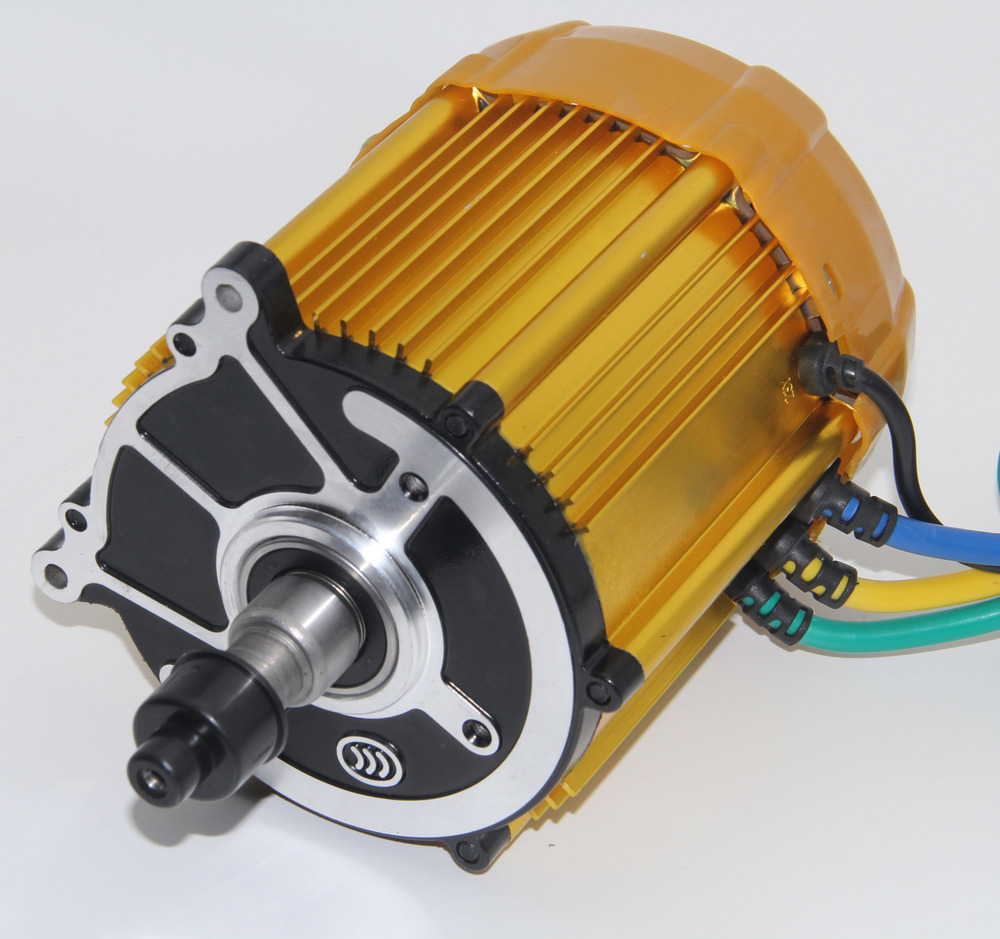

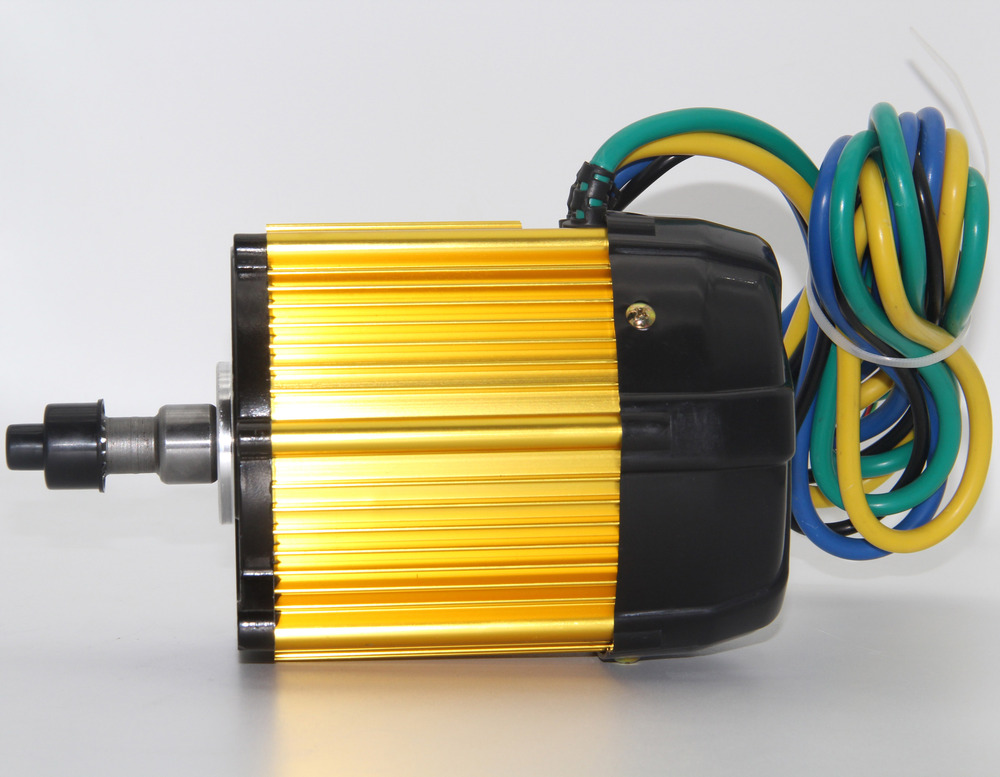

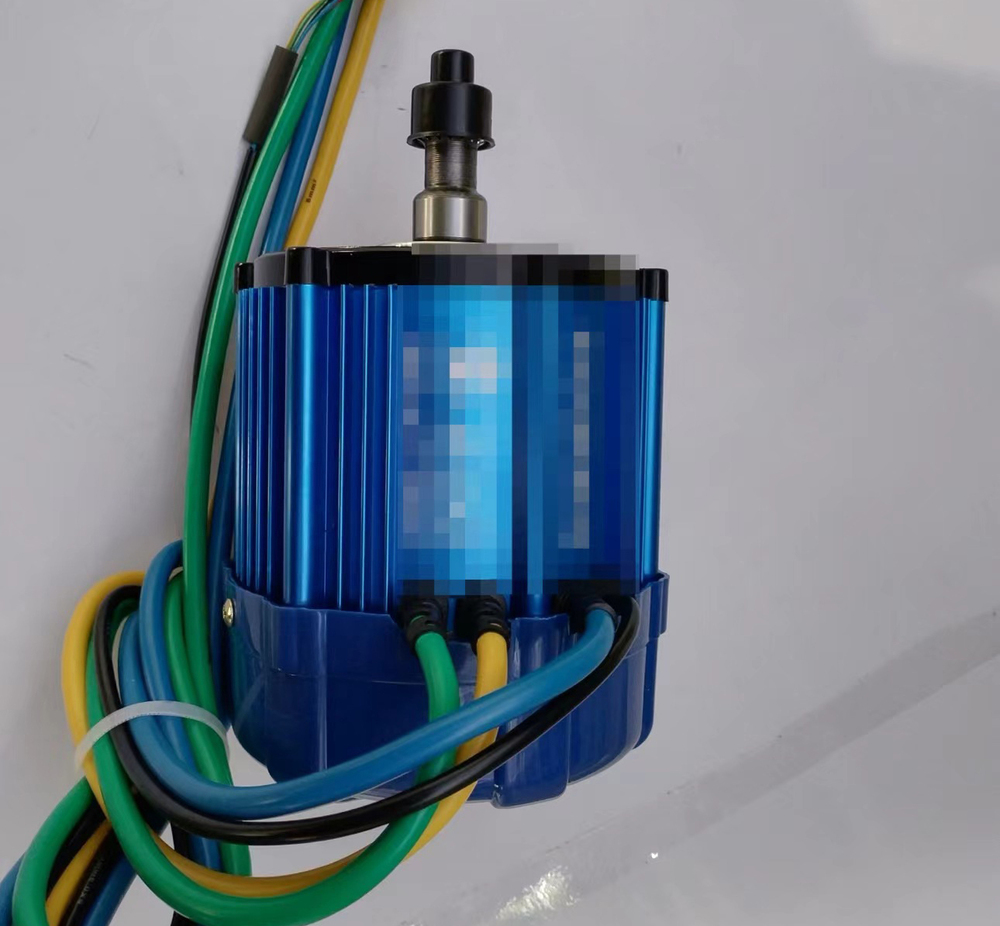

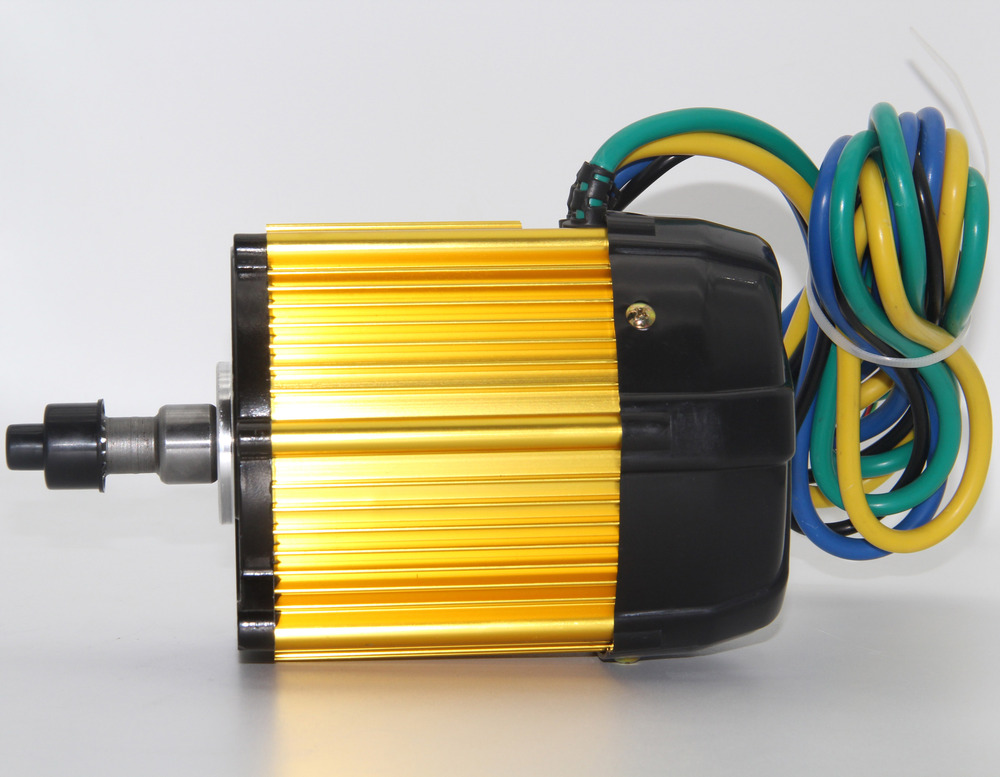

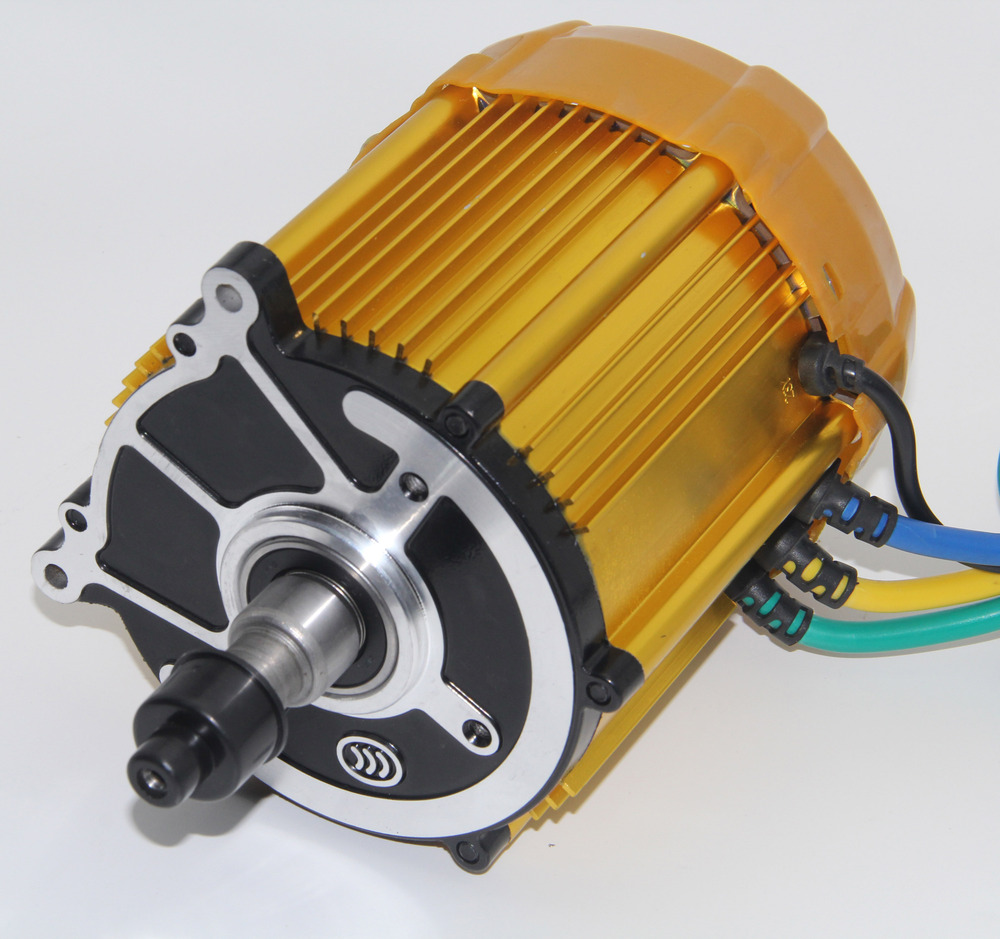

120 BLDC 48V 1200W RPM 3100 Rickshaw Motor

32 USD ($)/Piece

Product Details:

- Rated Frequency 50 Hz

- Ambient Temperature -20C to +50C

- Pressure Standard Atmospheric

- Current Type DC

- Starting Type Electric Start

- Rated Voltage 48V

- Efficacy High Efficiency

- Click to view more

X

120 BLDC 48V 1200W RPM 3100 Rickshaw Motor Price And Quantity

- 32 USD ($)/Piece

- 200 Piece

- Electric Rickshaw, E-Tricycle, E-Loader

- Yes

- Supported

- Upto 95%

- 42V - 54V

- Class F

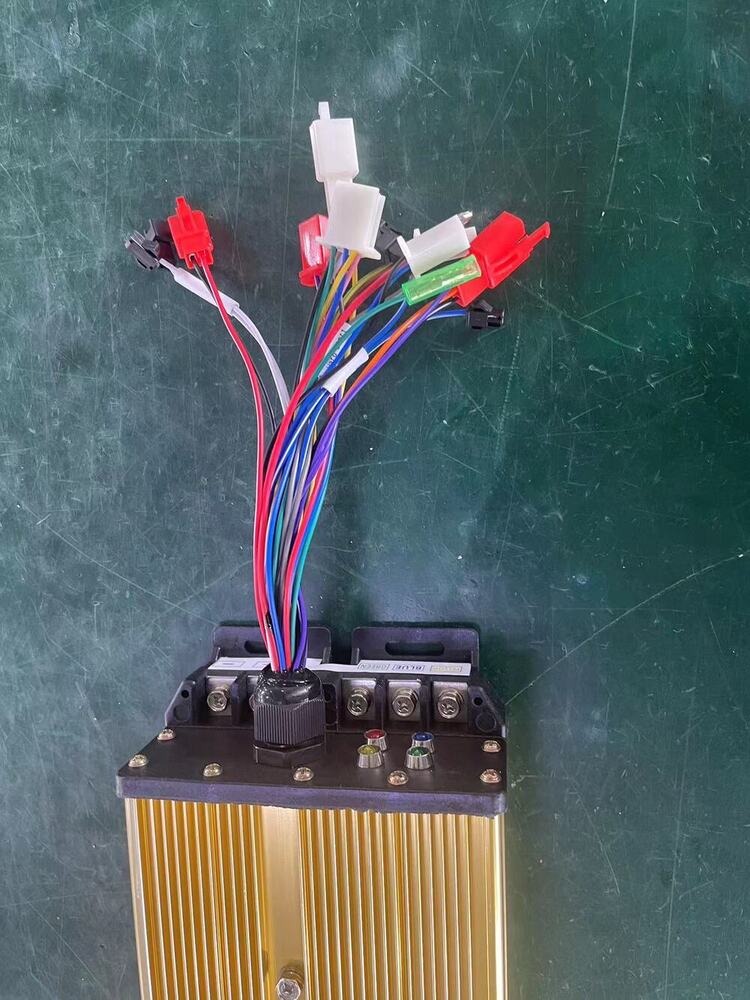

- 36/48V compatible controller

- 1 Piece

- Permanent Magnet

- > 10000 hours

- Yes

- 35A

- S1 (Continuous)

120 BLDC 48V 1200W RPM 3100 Rickshaw Motor Product Specifications

- DC

- Electric Start

- Overload Protection

- 28 mm

- 3100 RPM

- 50 Hz

- Standard Atmospheric

- -20C to +50C

- Flange Mount

- 1.6 HP

- IP54

- 4 Poles

- 1200 W

- High Efficiency

- 50 Hz

- 48V

- Air Cooled

- 38 Nm (max)

- Silver & Black

- Totally Enclosed

- Ball Bearing

- 1200W

- IS 14665 and IEC certified

- Less than 60 dB

- 320mm x 200mm x 180mm

- 48V DC

- Rickshaw Motor

- 1.2 kW

- 18 kg

- BLDC (Brushless DC Motor)

- Low Noise, High Efficiency, Robust Design, Long Life

- Three Phase

- Electric Rickshaw, E-Tricycle, E-Loader

- Yes

- Supported

- Upto 95%

- 42V - 54V

- Class F

- 36/48V compatible controller

- 1 Piece

- Permanent Magnet

- > 10000 hours

- Yes

- 35A

- S1 (Continuous)

Product Description

Changzhou Sino-Pan is a professional tricycle motor manufacturing enterprise integrating R&D, production and sales. With over 10 years of experience in the industry, it has always been committed to the mission of "providing efficient and reliable tricycle power systems for global users". Our core strength lies in technology as the foundation and quality as the priority. 1. Professional R&D team, 2. Full-scenario adaptation capability, 3. Strict quality control system, 4. Product matrix: Covering the entire chain of demands. Our products are exported to Southeast Asia, South Asia, Africa, the Middle East and other regions, and have won the trust of international customers with stable performance and localized services.Adaptable High-Performance Motor Solution

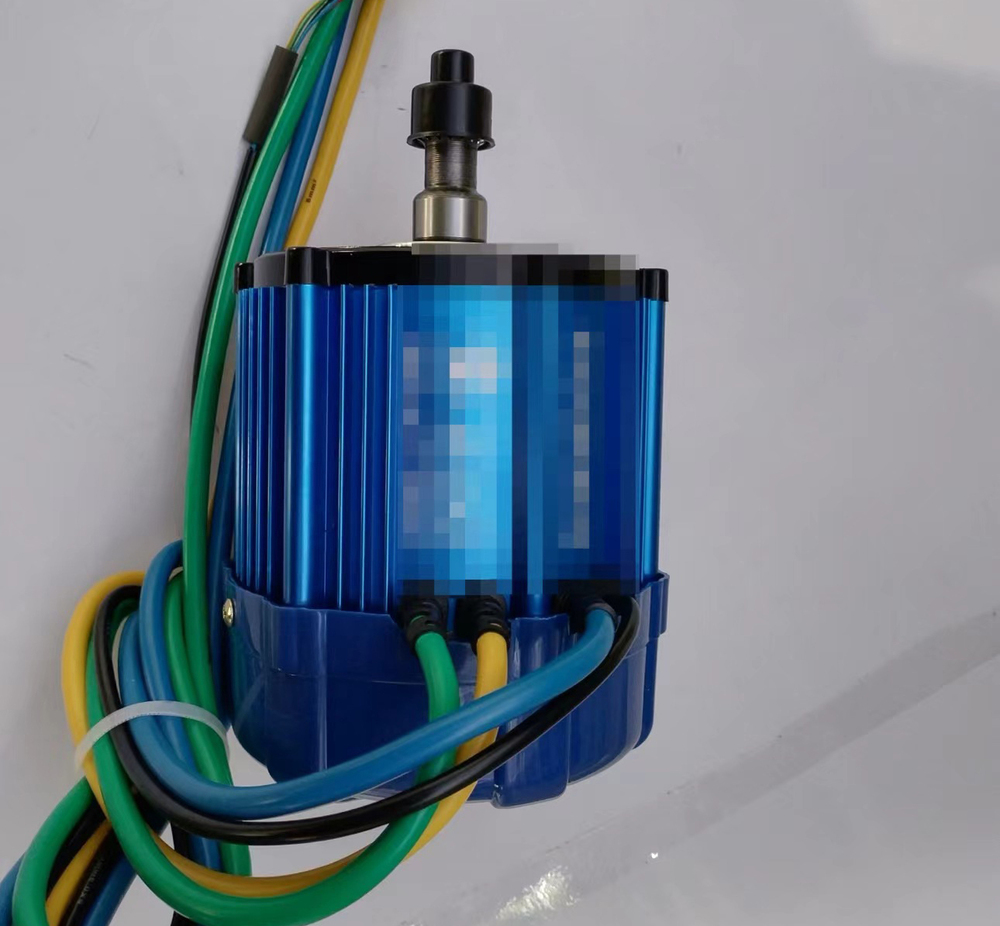

Designed for electric rickshaws, e-loaders, and tricycles, this BLDC motor delivers reliable performance with a 48V DC supply and 1200W output. Its gearless, air-cooled configuration allows continuous operation at a high efficiency, while compatibility with both 36V and 48V controllers ensures flexibility in system integration. The robust build is compliant with IS 14665 and IEC standards, offering peace of mind for manufacturers and end-users alike.

Built to Last in Demanding Conditions

Boasting an impressive life expectancy of over 10,000 hours, the motor is constructed for longevity. Its sealed, totally enclosed design with IP54 rating makes it suitable for use in environments with up to 95% humidity and temperatures ranging from -20C to +50C. Maintenance demands are minimized thanks to its brushless, permanent magnet rotor and ball bearing construction, making it an ideal choice for durable e-mobility.

Advanced Safety and Efficient Operation

Equipped with overload and reverse polarity protection, as well as regenerative braking support, this motor ensures secure and efficient operation. The three-phase, high-efficiency design maintains noise below 60 dB and torque up to 38 Nm, providing smooth and quiet rides. Flange mounting allows straightforward installation, and an electric start enables quick, hassle-free activation for all compatible vehicles.

FAQs of 120 BLDC 48V 1200W RPM 3100 Rickshaw Motor:

Q: How does the 120 BLDC 48V 1200W Rickshaw Motor benefit electric rickshaw operators?

A: This motor delivers high efficiency, low noise, and robust operation, reducing energy consumption and maintenance while ensuring a smooth ride experience. Its long lifespan and reliable protection features enhance vehicle uptime and operational cost savings.Q: What types of electric vehicles are compatible with this motor?

A: The motor is specifically designed for electric rickshaws, e-tricycles, and e-loaders, but its 48V configuration and 1200W power output make it suitable for various light electric commercial vehicles requiring continuous, high-torque operation.Q: Can the motor operate in humid or harsh environmental conditions?

A: Yes, with an IP54 rating and humidity resistance up to 95%, the motor can function reliably in challenging weather and industrial environments. Its completely enclosed, robust design protects internal components from dust and moisture.Q: What controllers can be used with this rickshaw motor?

A: This 1200W BLDC motor is compatible with both 36V and 48V DC motor controllers. Integration with regenerative braking-capable controllers is supported for improved energy efficiency during braking cycles.Q: How is reverse polarity and overload protection provided in this motor?

A: The motor incorporates internal safety circuits that automatically prevent damage from incorrect wiring (reverse polarity) or excessive current draw (overload), thereby protecting the equipment and users from operational faults.Q: Where is this motor typically mounted and what is the installation process?

A: The motor features a flange mounting type and a shaft diameter of 28 mm, allowing secure installation on standard e-rickshaw frames. Professional installation by a qualified technician is recommended to ensure proper alignment and performance.Q: What is the process for maintaining this BLDC motor?

A: Minimal maintenance is required due to the brushless design and quality ball bearings. Regular cleaning of the exterior and checking for secure electrical connections will help ensure optimal motor performance and longevity.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese